1.6mm-19mm Easy Processed Clear Float Glass

Production Advantages:

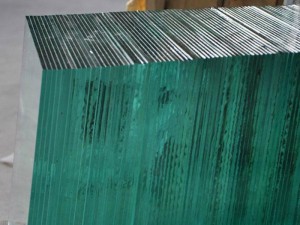

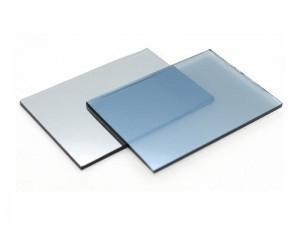

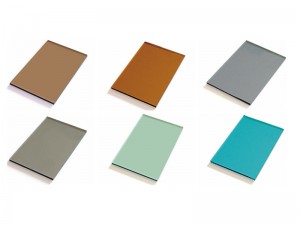

Versatility is the reason why clear float glass is the glass of choice for applications in the construction, decorative, automotive, and high-tech sectors. It can be processed in every imaginable way and is often used as a base glass for an entire range of glass products including:

Mirrors and back-painted glass

Acid-etched glass

Tempered and laminated glass

Safety and security glass

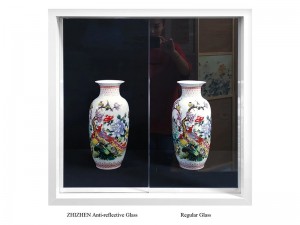

Coated glass such as solar-control glass and insulating glass

Double glazing and triple glazing

Jinjing depends on the advanced technology and equipment to improve the glass product quality, and has made outstanding achievement in high quality float glass filed. We have produced PDP glass, automobile glass, mirror glass, coating glass etc., and it has been widely recognized by our customers and widely used in electrical panel, optics device panel, automotive windshield and so on. From float glass, tinted glass, ultra clear glass to online Low-E, offline Low-E and corresponding processed glass, the entire glass industry chain production enables Jinjing to provide customers with professional and differentiated glass solutions. Relying on the cumulative expertise of glassmakers and production teams throughout the world, Jinjing continually applies science and cutting-edge technology to the development of new advanced architectural glass products that expand the limits of performance.

Why choose Jinjing?

1, Good quality, easy to processing (cut, edge, drill, heat-treat, bend, tempering, coating, laminating, insulating, mirror and etc.).

2, Excellent optics performance.

3, Complete specifications, cut to size available, reduce cutting loss.

4, Use clean energy, green and environment protection.

5, More than 20 years export experience with good packaging & loading.

Optical Parameters

| Thickness | Visible Light Transmittance | Visible Light Reflectivity | Solar Transmittance | Solar Reflectivity | Visible-Infrared Transmittance | Ultraviolet Transmittance |

| 2 | 90.69 | 8.3 | 87.22 | 7.9 | 84.15 | 83.44 |

| 2.5 | 90.47 | 8.3 | 86.14 | 7.8 | 82.31 | 81.97 |

| 2.8 | 90.34 | 8.3 | 85.51 | 7.7 | 81.22 | 81.15 |

| 3 | 90.25 | 8.3 | 85.09 | 7.7 | 80.51 | 80.62 |

| 3.2 | 90.17 | 8.3 | 84.67 | 7.7 | 79.80 | 80.11 |

| 4 | 89.82 | 8.3 | 83.04 | 7.6 | 77.03 | 78.18 |

| 5 | 89.39 | 8.2 | 81.07 | 7.4 | 73.71 | 76.02 |

| 6 | 88.96 | 8.2 | 79.17 | 7.3 | 70.54 | 74.08 |

| 8 | 88.31 | 8.1 | 76.51 | 7.1 | 66.14 | 70.60 |

| 10 | 87.47 | 8.1 | 73.61 | 6.9 | 61.56 | 67.15 |

| 12 | 86.25 | 8.0 | 68.53 | 6.6 | 53.09 | 66.23 |